Carabiner failure is a serious concern for aerialists, as it can compromise safety and performance. This guide dives into the common causes of failure, troubleshooting tips, and preventative measures to help you maintain reliable equipment. By understanding these issues and following best practices, you can minimize risks and concentrate on your aerial artistry..

Understanding Carabiners and Swivels

Before we dive into troubleshooting, let’s briefly understand what carabiners and swivels are and why they’re essential in aerial arts.

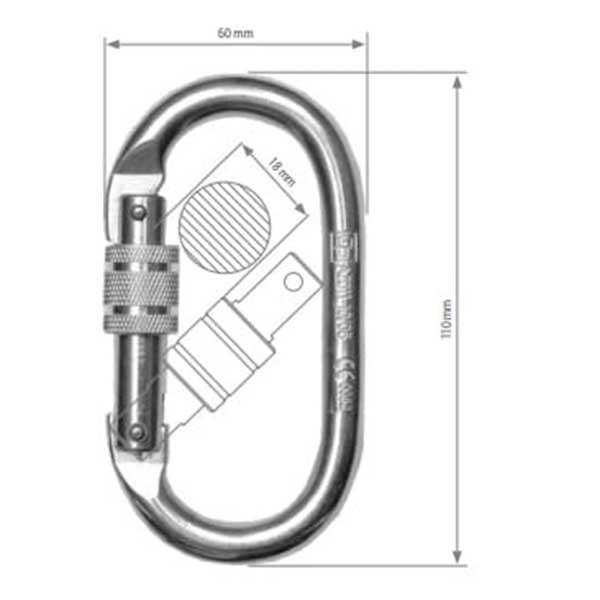

Carabiners

These are metal loops with a locking gate that are used to connect ropes, slings, and other equipment to your harness. They are the backbone of aerial rigging, providing the necessary support for your aerial performances.

Swivels

These are rotating connectors that help prevent rope twist and ensure smooth movement during aerial maneuvers. They are typically used between the rope and the carabiner, reducing the risk of equipment failure.

Common Causes of Carabiner Failure

While carabiners are designed for durability, certain issues can lead to failure:

- Gate Malfunction: A stuck or improperly closing gate can compromise your rigging.

- Corrosion: Exposure to moisture or chemicals can weaken the metal over time.

- Wear and Tear: Frequent use can cause structural damage, increasing the risk of breakage.

- Improper Use: Using carabiners for tasks outside their intended purpose can fail.

Troubleshooting Carabiner and Swivel Issues

If you suspect carabiner failure, follow these steps to identify and address the problem:

- Inspect for Damage: Look for cracks, bends, or any signs of wear. Damaged carabiners should be replaced immediately.

- Test the Gate: Ensure the gate opens and closes smoothly. A malfunctioning gate is a safety hazard.

- Check for Corrosion: Examine all metal surfaces for rust or discoloration. Replace corroded equipment promptly.

- Consult a Professional: If you’re uncertain about the condition of your equipment, seek advice from an aerial rigging expert.

Preventing Carabiner Failure

To reduce the risk of carabiner failure, implement these preventative measures:

- Regular Inspections: Inspect your carabiners and swivels before and after each use.

- Proper Storage: Store your equipment in a dry, clean space to prevent corrosion.

- Avoid Overloading: Never exceed the weight limits specified by the manufacturer.

- Follow Manufacturer Guidelines: Use your carabiners and swivels according to their intended purpose.

FAQs

Q: How often should I replace my carabiners and swivels?

A: The lifespan of carabiners and swivels can vary depending on factors such as usage frequency, storage conditions, and maintenance. As a general rule, it’s recommended to replace your equipment every 5-7 years, even if it appears to be in good condition.

Q: Can I repair a damaged carabiner or swivel?

A: It’s generally not recommended to repair damaged carabiners or swivels. Even minor damage can compromise the structural integrity of the component, increasing the risk of failure. It’s always safer to replace damaged equipment.

Conclusion: Protect Yourself from Carabiner Failure

By understanding the causes of carabiner failure and implementing proper care and maintenance, you can ensure the safety of your rigging. Regular inspections, proper storage, and adherence to usage guidelines are essential to preventing issues.

For high-quality carabiners and swivels designed for aerialists, visit the Vertical Wise Shop. Upgrade your rigging with reliable equipment that meets the demands of your art.